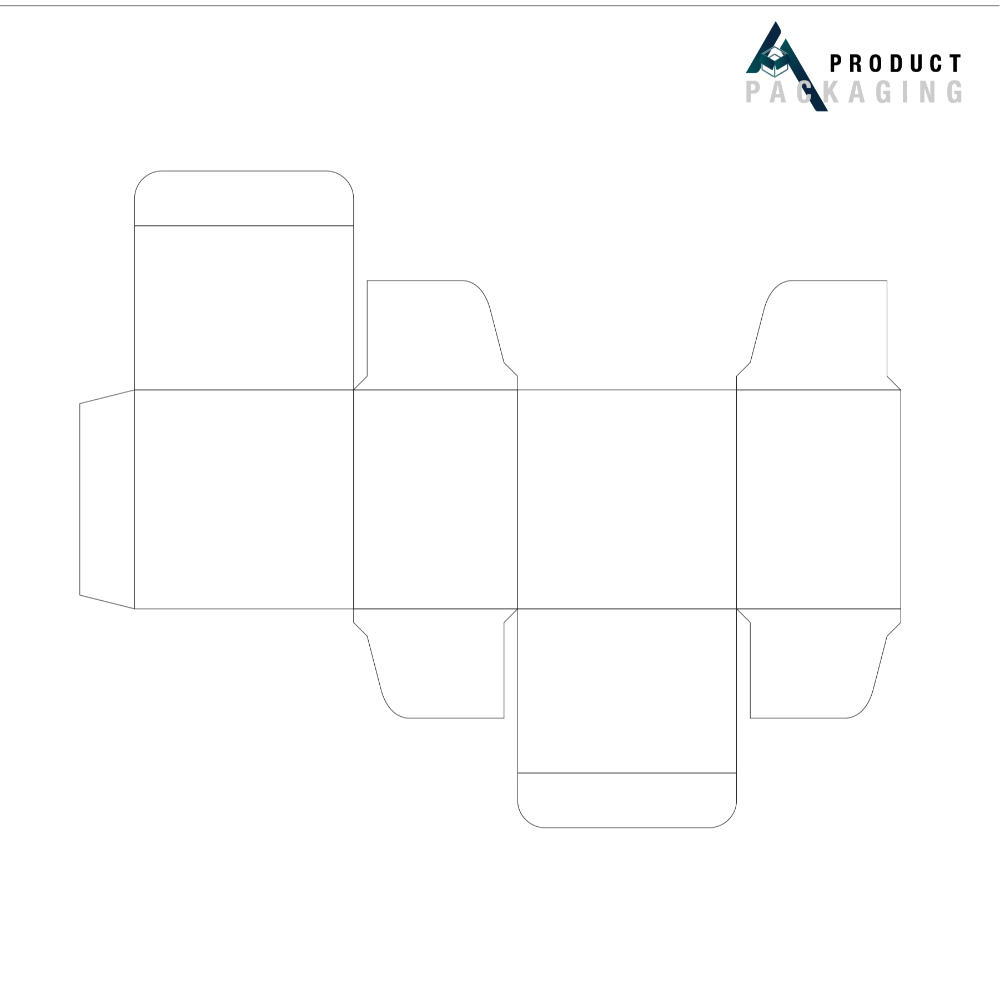

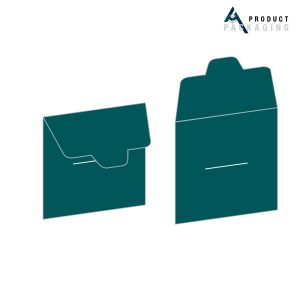

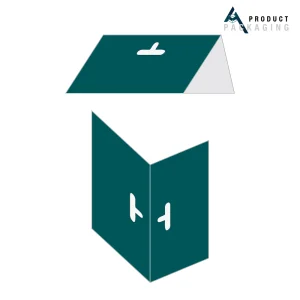

Tuck End Box

Our Tuck End Boxes are a smart and versatile packaging choice, made from durable cardstock, corrugated, or eco-friendly Kraft materials. Fully customizable in size, style, and print, they’re ideal for packaging cosmetics, food items, electronics, CBD products, and more. With precise die-cutting, high-quality printing, and a range of finishes, these boxes ensure your product stands out while staying protected. Affordable, lightweight, and shipped flat, tuck end boxes offer both branding power and practicality.

No Die & Plate Charges

Quick Turnaround Time

Free Shipping

Custoimze Size & Style

Free Designing

Cmyk Printing

CMYK printing is a color printing process using cyan, magenta, yellow, and black inks for full-color images.

Digital Printing

Digital printing is a modern method that directly prints digital images onto various materials without printing plates.

Metallic Pantone

Metallic Pantone refers to special ink shades with a metallic finish, offering a shiny and premium appearance.

Pantone Color Cmyk

Pantone Color CMYK refers to converting Pantone spot colors into CMYK values for four-color process printing.

Screen Printing

Screen printing is a technique that uses a mesh stencil to transfer ink onto a surface, creating vibrant designs.

Offset Printing

Offset printing is a high-quality printing technique that transfers ink from a plate to a rubber blanket, then to paper.

Anti Scratch Lamination

Anti-scratch lamination is a protective film that enhances durability and prevents scratches on printed surfaces.

Gloss Lamination

Gloss lamination is a shiny, protective coating that enhances colors and adds a smooth, reflective finish to prints.

Matte Lamination

Matte lamination is a soft, non-glossy protective coating that gives prints a smooth, elegant, and glare-free finish.

Spot UV

Spot UV is a printing technique that applies a glossy, raised coating to specific areas for a striking contrast.

Varnish

Varnish is a clear coating applied to printed materials for protection and to enhance their finish, either glossy or matte.

Soft Touch Lamination

Soft-touch lamination is a velvety, matte coating that enhances prints with a smooth, luxurious, and tactile feel.

foiling

embossing

Dembossing

Spot UV

foiling

embossing

Dembossing

Spot UV

White card

Kraft card

corrugation

special card

White card

Kraft card

corrugation