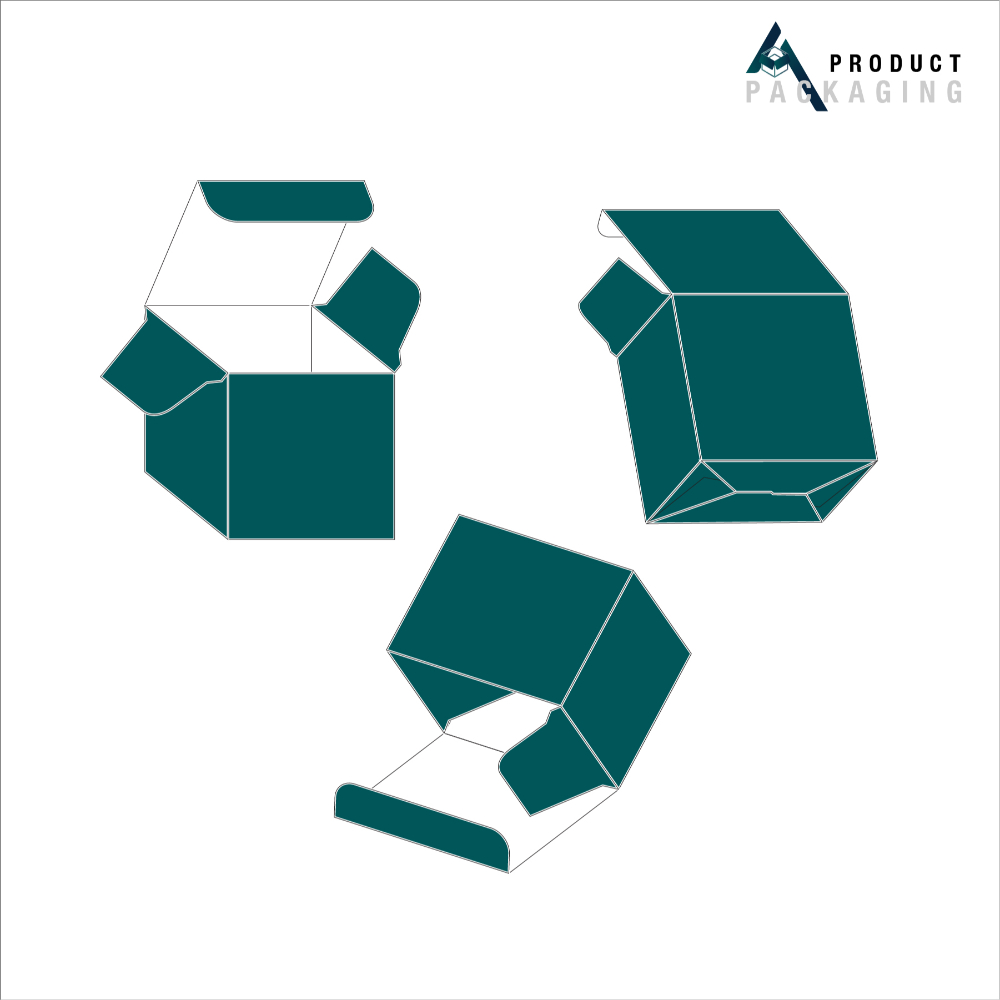

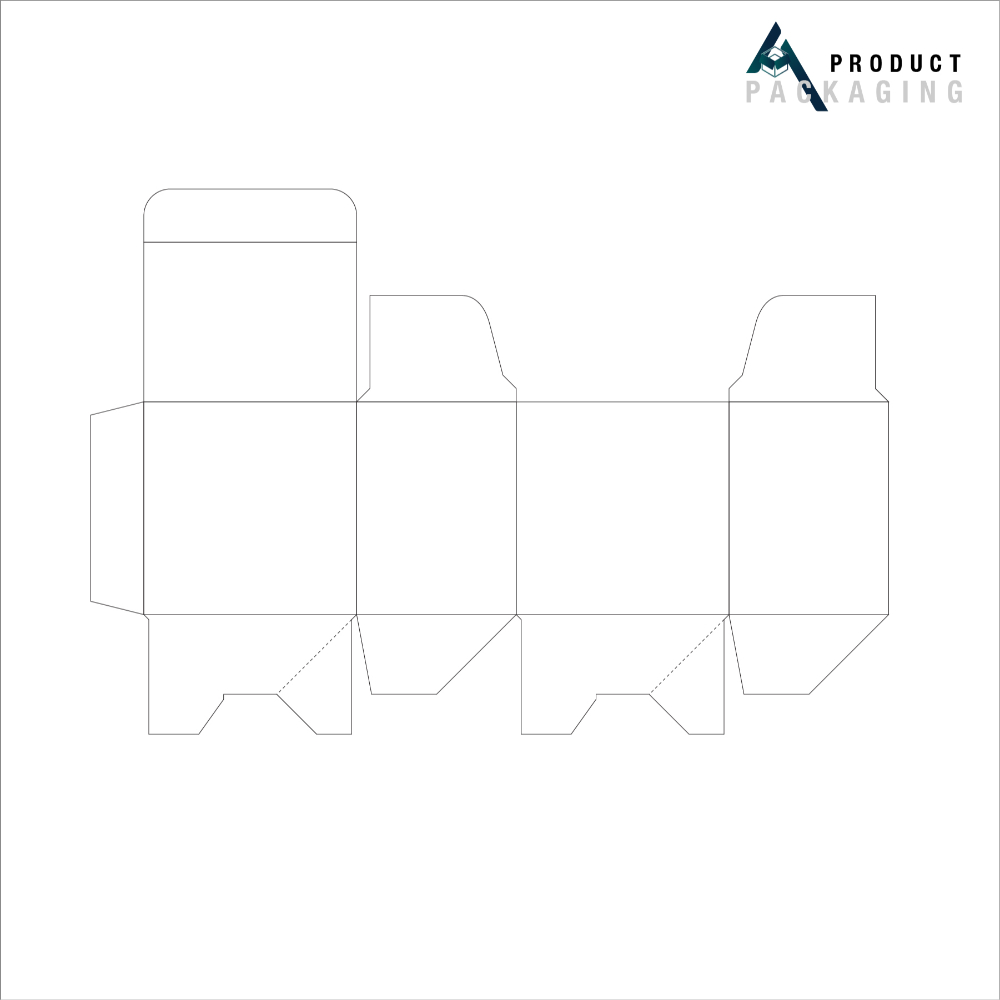

Tuck End Auto Bottom

Tuck End Auto Bottom boxes combine quick assembly with sturdy protection, ideal for efficient packaging. Crafted from durable materials, these boxes feature an easy tuck closure on top and an auto-locking bottom for secure support. Fully customizable in size, printing, and finish, they are perfect for retail, food, cosmetics, and wholesale packaging needs. Fast to assemble and strong in design, these boxes offer a smart solution for brands seeking both convenience and quality.

Request A Quotes!

Free Designing

Quick Turnaround Time

Free Shipping

Custoimze Size & Style

Finishing Options

Cmyk Printing

CMYK printing is a color printing process using cyan, magenta, yellow, and black inks for full-color images.

Digital Printing

Digital printing is a modern method that directly prints digital images onto various materials without printing plates.

Metallic Pantone

Metallic Pantone refers to special ink shades with a metallic finish, offering a shiny and premium appearance.

Pantone Color Cmyk

Pantone Color CMYK refers to converting Pantone spot colors into CMYK values for four-color process printing.

Screen Printing

Screen printing is a technique that uses a mesh stencil to transfer ink onto a surface, creating vibrant designs.

Offset Printing

Offset printing is a high-quality printing technique that transfers ink from a plate to a rubber blanket, then to paper.

Anti Scratch Lamination

Anti-scratch lamination is a protective film that enhances durability and prevents scratches on printed surfaces.

Gloss Lamination

Gloss lamination is a shiny, protective coating that enhances colors and adds a smooth, reflective finish to prints.

Matte Lamination

Matte lamination is a soft, non-glossy protective coating that gives prints a smooth, elegant, and glare-free finish.

Spot UV

Spot UV is a printing technique that applies a glossy, raised coating to specific areas for a striking contrast.

Varnish

Varnish is a clear coating applied to printed materials for protection and to enhance their finish, either glossy or matte.

Soft Touch Lamination

Soft-touch lamination is a velvety, matte coating that enhances prints with a smooth, luxurious, and tactile feel.